RPWORLD has been engaging in high-mix, low-volume manufacturing service 2003. Over almost 20 years’ development, RPWORLD has been providing customized one-stop manufacturing solutions for nearly 20,000 projects from 40 countries around the globe, becoming one of the fastest and most comprehensive manufacturing suppliers around the world.

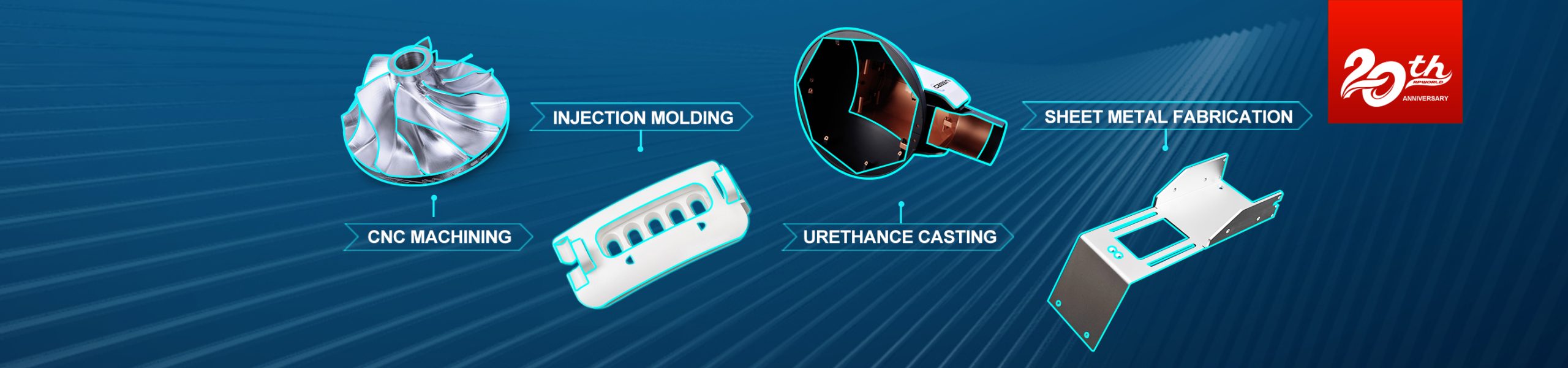

CNC Machining at RPWORLD meet the diverse needs of clients ranging from single part to low- to mid-volume production. Our CNC machines run 24/7, ensuring that your high precision, complex geometries parts delivered in as fast as 3 days. We have equipped with 3-axis, 4-axis, and 5-axis machines, drilling machines, lathe machines and EDM, which are designed for creating complex shapes with high precision. The cutting-edge machines offer tight tolerances DIN ISO 2768 medium (fine), and wide machining range from 1mm to 1600mm.

The Injection Molding process at RPWORLD produces on-demand injection molded parts in as fast as 7 days. We equip with the large injection molding machine which offers the maximum clamping force range with 480tons, and automatic arms ensuring the production 24/7. Plus, we are capable of designing, machining, modifying, and even reserving molds. That’s why you can enjoy the one-stop shop capabilities ranging from prototyping to end-use production.

The Urethane Casting Department process at RPWORLD is committed to rapid prototypes or low-volume parts in as fast as 7 days. We are capable of making complex-geometries parts with solid color, textures and transparency. In addition, overmolding and insert molding are also available here to meet your different applications.

RPWORLD Sheet Metal Fabrication service, including cutting, bending, and stamping, is designed for rapid prototyping and end-use production. You can expect sheet metal parts with secondary options such as finishing options and pre-assemblies. Furthermore, you can receive in-depth analysis for your part design within 24 hours.

When customers have high requirements on the quality and accuracy of mechanical parts, and the quantity is relatively small, CNC Machining is the most suitable process. Our rich experience in plastic processing makes us have excellent ability in processing metal parts.With dozens of CNC machines, including milling, turning, drilling, and engraving machines, we can process various of parts and products with multiple materials like stainless steel, soft metal and hard normalized steel etc.

The injection molding process is the most common, most important and economical process for the mass production of plastics, especially high performance engineering plastics. We offer rapid tooling (prototype tooling), trial tooling ( bridge tooling ), hardened tooling, low volume production, high-volume production (mass production) and on-demand production.

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shape from a 3D model or other electronic data source primarily through additive processes in which successive layers of material are laid down under computer control. Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. At RPWORLD, additive manufacturing is designed for functional prototypes, complex designs, and production components.

The quality of the surface treatment determines the value and ultimately the success of a product. That’s why we go the extra mile. RPWORLD offers a variety of surface finishes to meet the customer requirements.

Sheet metal is metal formed by an industrial process into thin and flat pieces. It is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin thicknesses are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate. At RPWORLD, our sheet metal fabrication service is designed for rapid prototyping, end-use production and assemblies.

Design for manufacturing (also sometimes known as design for manufacturability or DFM) is the general engineering practice of designing products in such a way that they are easy to manufacture. At RPWORLD, our professional DFM service describes the process of designing or engineering a product in order to facilitate the manufacturing process with the purpose of reducing manufacturing costs, accelerating production time and improving products quality.